Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

DG VIFORT Technical Guide: Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

【Published by DG VIFORT | Focus: Industrial Electronics, Precision Manufacturing, and High-Reliability Applications】

In high-performance electronic devices and precision industries, the surface treatment of fasteners is crucial for determining long-term reliability, electrical performance, and cosmetic quality. DG VIFORT has compiled this comprehensive guide to help engineers and procurement specialists quickly and accurately select the most suitable surface treatment for their application requirements.

I. Quick Reference Table: Fourteen Mainstream Processes

This table is categorized into three tiers based on functionality, cost, and performance, detailing the core concerns for the industrial electronics sector.

| Rank | Process Name | Popularity | Core Function & Features | Cost Description | Typical Salt Spray Test |

| Economical & General Corrosion Protection | |||||

| 1 | Zinc Plating | Very High | Most economical and common, good dimensional accuracy. High-strength parts require hydrogen embrittlement relief. | Very Low | Blue/White Zinc: $\ge 48\text{h}$ |

| 2 | Phosphating | Very High | Primary role: Improves torque consistency, often used for self-tapping screws and as a primer coat. | Very Low | With Oil: $\ge 12-24\text{h}$ |

| 3 | Black Oxide | Common | No dimensional increase, suitable for dimension-sensitive parts. Must be sealed with oil, poorest corrosion resistance. | Very Low | With Oil: $\ge 6-12\text{h}$ |

| 4 | Stainless Steel Passivation | Common | Only for Stainless Steel. Enhances inherent corrosion resistance and removes surface free iron. | Low | Assessed by Rust Test |

| Functional & Medium-High Performance | |||||

| 5 | Nickel Plating | Common | Provides conductivity and solderability. Electroless Nickel (ENP) is more uniform (for precision). | Medium | With Oil: $\ge 8-24\text{h}$ |

| 6 | Nitriding / QPQ | Special | Surface hardening process that significantly enhances hardness, wear resistance, and fatigue strength. | Higher | QPQ: $\ge 72-120\text{h}$ |

| 7 | Silver Plating | Dedicated | Best conductivity (lowest resistance). Used for high-current/high-frequency communication. Tends to tarnish. | Expensive | Usually $< 24\text{h}$ |

| 8 | Tin Plating | Special | Excellent electrical contact and solderability. Common in electronic connectors. | Medium | Usually $< 48\text{h}$ |

| 9 | Copper Plating | Special | Excellent conductivity, often used for Electromagnetic Shielding (EMC). Very poor corrosion resistance. | Low | $< 24\text{h}$ |

| 10 | Dacromet | Very High | Hydrogen-embrittlement-free, high corrosion and heat resistance ($250^\circ\text{C}$). Best choice for high-strength parts. | Low | High Perf: $\ge 240\text{h}$ |

| 11 | Electrophoresis (E-Coat) | Common | Uniform paint film, high cosmetic quality. Rack plating leaves a contact point, requires base plating for full protection. | Low | Black: $\ge 240-480\text{h}$ |

| Highest Performance & Dedicated | |||||

| 12 | Zinc-Nickel Alloy Plating | High Perf | Highest corrosion resistance among plating. Strong, heat-resistant. Best eco-friendly alternative to hexavalent chromium. | Medium | $\ge 240\text{h} \sim 1000\text{h+}$ |

| 13 | Chrome Plating | Special | Hard Chrome: Extreme hardness/wear resistance. Decorative Chrome: Bright finish (requires Nickel base). | Higher | Depends on base layer |

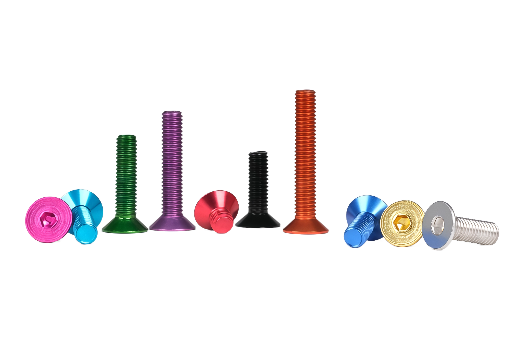

| 14 | Anodizing | Dedicated | Only for Aluminum fasteners. Forms a hard, wear-resistant, colorable oxide film. | Higher | $\ge 48-240\text{h}$ |

| 15 | Teflon Coating | Special | Self-lubricating, chemical-resistant, anti-stick. Solves high-torque consistency or chemical corrosion issues. | Expensive | $\ge 72-200\text{h}$ |

II. Selection Focus for Electronics and Precision Applications

In the industrial electronics sector, functional requirements often outweigh simple corrosion protection. DG VIFORT advises focusing on these critical decision points:

1. Tiered Selection for Conductivity and Solderability

Ultimate Conductivity (Cost Expensive): Silver Plating. Suitable for high-current, high-frequency communication, and ultra-low contact resistance requirements.

Solderability and Connection (Cost Medium): Tin Plating. Used for terminals requiring soldering or reliable electrical contact.

EMC Shielding (Cost Low): Copper Plating. Utilizes its excellent conductivity for electromagnetic shielding, but note its very poor corrosion resistance.

2. Precision Control and Coating Uniformity

Electroless Nickel Plating (ENP): The preferred choice for precision fasteners. Through autocatalytic reaction, the coating thickness is extremely uniform, independent of the screw geometry, ensuring thread fit accuracy. * Black Oxide: If dimensional accuracy is critical (micron-level) and the application environment is dry indoor, Black Oxide (non-dimensional increase) can be chosen.

3. High Performance and Safety Assurance

Zinc-Nickel Alloy Plating: If the product faces harsh corrosion (e.g., engine compartment, marine climate) and needs to replace hexavalent chromium, Zinc-Nickel Alloy is the most reliable electroplated solution, offering salt spray protection up to $1000\text{h}$ or more.

Nitriding / QPQ: When fasteners are subjected to high stress and wear (e.g., certain transmission or mold parts), Nitriding significantly enhances their surface hardness and fatigue life.

4. Critical Process Risks and Countermeasures

Hydrogen Embrittlement Risk: For high-strength bolts grade 10.9 and above, Zinc Plating must undergo strict hydrogen relief; Dacromet is the inherently hydrogen-embrittlement-free option.

E-Coat Contact Point: Electrophoresis (E-Coat) and Powder Coating leave an uncoated area at the contact point where the part is racked. DG VIFORT recommends a "Zinc Base Plating + E-Coat Topcoat" composite process to ensure the contact point still has basic corrosion protection.

III. DG VIFORT Quick Selection Summary

| Your Requirement Is... | Recommended Process | Key Consideration |

| General Corrosion & Budget-Friendly | Zinc Plating | Cost Very Low, suitable for general indoor/outdoor. |

| High Strength, No H-Embrittlement, Heat Resist. | Dacromet | Cost Low, proven in automotive sector. |

| Highest Corrosion Reliability | Zinc-Nickel Alloy | Cost Medium, salt spray performance outstanding. |

| Extreme Low Contact Resistance | Silver Plating | Cost Expensive, ultimate conductivity. |

| Precision Thread, Dimensional Stability | Electroless Nickel (ENP) | Cost Higher, guarantees mating accuracy. |

| Stainless Steel Parts | Passivation | Cost Low, removes free iron, ensures inherent corrosion resistance. |

DG VIFORT is committed to providing precision fasteners that meet the demands of various stringent applications. For customized solutions or in-depth technical support, please contact our team of technical experts.

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications